Our project, Merriman Road, has been featured in the Architects’ Journal.

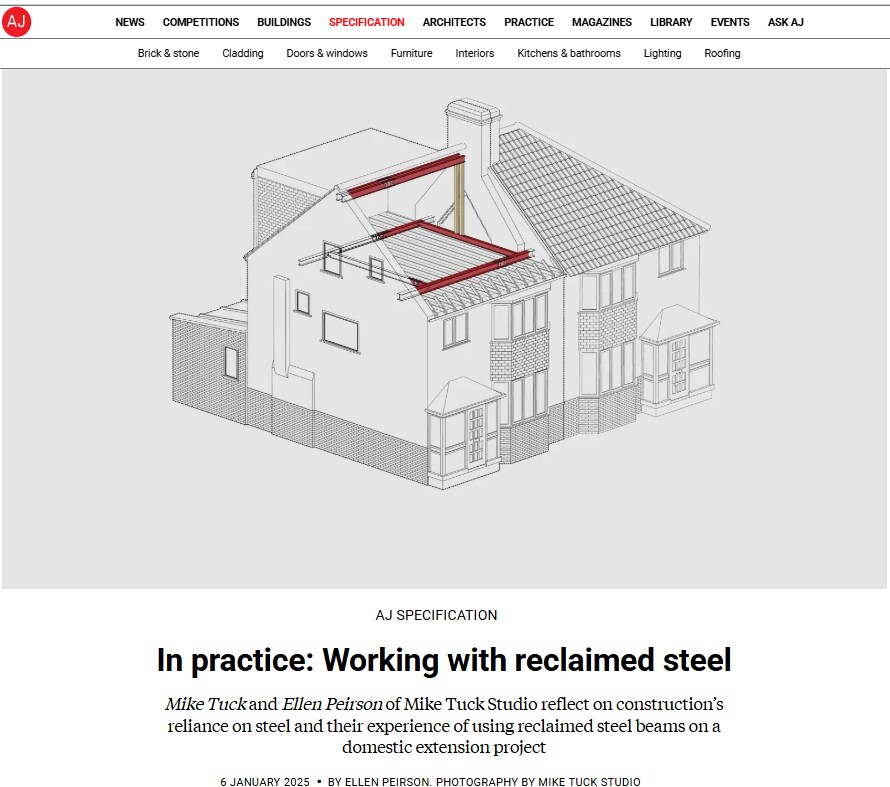

The brief for Merriman Road was to extend into the loft and to the rear of a private home in south east London. Our client was keen to reuse as much of the existing structure as possible and achieve a low carbon design. We collaborated with Mike Tuck Studio on the design and considered various structural options to meet the client and Architect aspirations.

Our engineers undertook carbon calculations to demonstrate how much carbon could be saved by installing reclaimed steels vs new steel. Using reclaimed steel produced a SCORS rating of A++ and saved 23kg CO2e/m2 compared to the new steel option.

Mike Tuck and Ellen Peirson of Mike Tuck Studio have shared insights and the team’s experience of the process of reusing steels on this project.

For Evans (our client), the choice to create a room in the roof space could only be justified if the carbon impact of the new structure could be kept to a minimum. As such, reclaimed steel was the only option. Thus began a rich and educational journey into how to use reclaimed steel, for a consumer client, at a small scale.