The aim of this home renovation project at Wandsworth House was not to increase the amount of space, but rather improve the quality and the use of it.

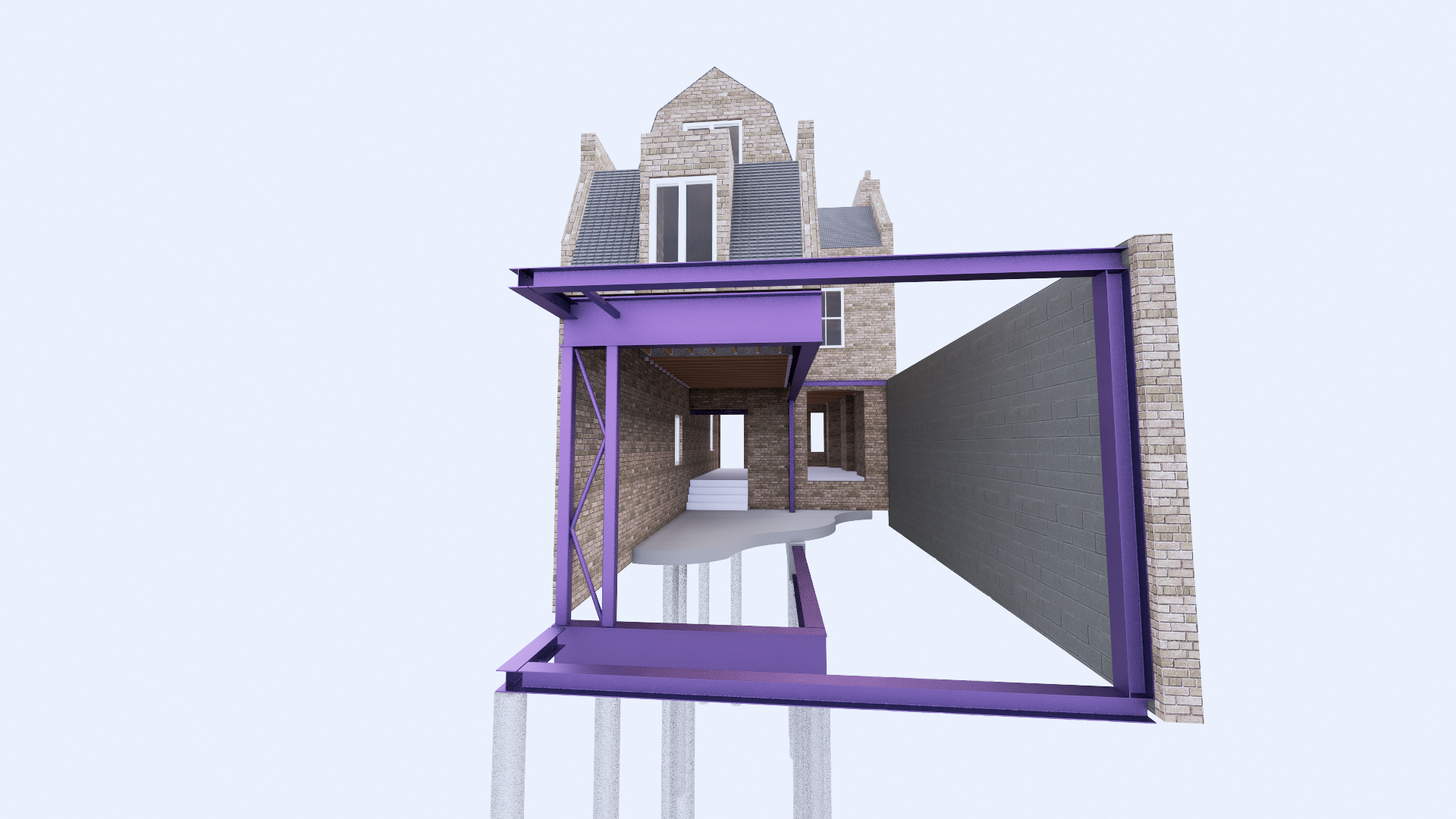

The existing building was built in the late 1800s and is a three-storey home with load bearing brick walls and timber floors spanning front to back. A rear extension was added in the early 2000s but the condition of it had deteriorated and needed replacing.

Our client wanted a striking focal point to their extension, one which would be flooded with natural light, and which clearly distinguished between the existing and the new.

We relish a challenge and enjoy thinking outside the box to deliver different options.

We collaborated closely with Finkernagel Ross on various design iterations before arriving at the perfect solution – a completely column-free space to give a definite wow factor.

Both the side and rear outrigger walls at ground level were replaced with a double cantilever steel structure, nearly 9m long by 3m wide, and supports the upper outrigger levels and a fully glazed roof at ground floor.

The cantilever structure required careful detailing with the steel beams concealed using brick slips, and provides a seamless support to the glazed roof without any visible structure resulting in the glass appearing to pass through the brickwork.

The steelwork to the front and rear of the cantilevered structure provides framing to the perimeter of the glazing, allowing the centrepiece of the double cantilever to float.

One of the main challenges of cantilevered structures is deflection. A simple solution would be to increase steel member sizes, however this adds cost and carbon to the project while reducing the head height of the space.

To minimise the size and weight of the beams, we developed a system to temporarily support the upper levels while the steelwork was installed, then carefully pre-loaded the frames to transfer the building weight and ensure any movements or deflections were within acceptable limits.

To significantly reduce the amount of concrete used in the foundations, saving our client money and reducing the embodied carbon associated with the foundations, we designed a piled ground beam solution instead of a typical reinforced pad foundation system.