Our Mary Ward Centre project has been featured in the Architects’ Journal.

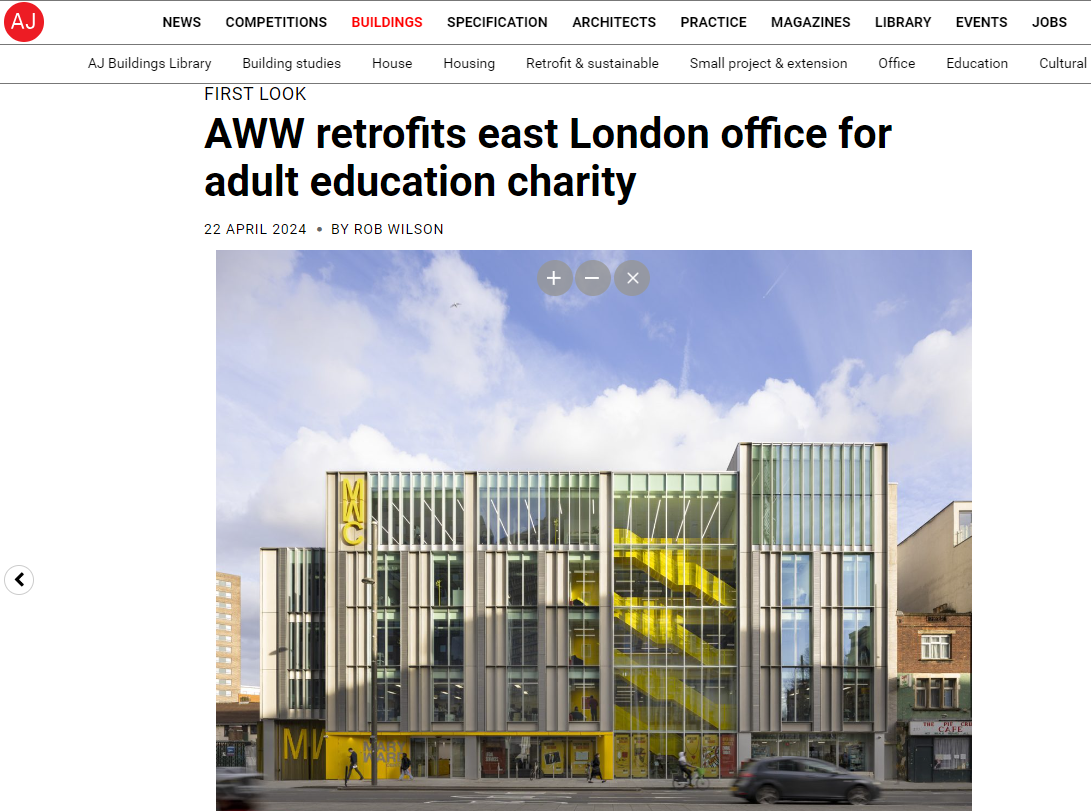

We worked with AWW to transform a disused three-four storey office building in Stratford, adding a vertical extension of two extra storeys and a full refurbishment to cater for the expanding needs of Mary Ward Centre, a century old adult education charity.

Mary Ward Centre were previously operating from a Grade II listed building in Queen’s Square, London but required larger premises due to their expanding services.

They identified Queensway House, now Mary Ward Centre – a derelict 1970s concrete framed building – as a potential new home.

Mary Ward obtained a loan from the ‘Skills for Londoners Capital Fund’ to renovate Queensway House. Environmental considerations were crucial, requiring the reuse of the existing frame for funding approval.

The two additional storeys are constructed using steel framing and concrete slab on metal deck. New steelwork strengthens the existing slabs and columns, left exposed to highlight the interface between the new and existing structural modifications. An exposed structure suited the budget and low carbon design goals.

We implemented a rigorous process of investigation, calculation, and verification to ensure we designed an efficient building and avoided the use of unnecessary materials. Working with the existing structure we aimed to minimise interventions, collaborating closely with the design team to utilise the building’s capacity where possible. This involved numerous design iterations and close collaboration.

The frame was fully modelled in Revit, our technicians used the EOC ECO2 plug-in to calculate the volume of new material and the Structural Carbon Tool for CO2 amounts for individual elements. The refurbishment option demonstrated a 40% reduction in embodied carbon when compared to constructing a new building, excluding demolition of the frame, with the refurbishment and extension meeting LETI’s targets.

Saving the existing structure had its challenges but resulted in an estimated embodied carbon saving of over 300 tCO2e (Modules A1-A5) when compared to an equivalent new build approach.

Joe Knowles, associate architect, AWW, AJ 22.04.24