The latest Intergovernmental Panel on Climate Change (IPCC) report was published last week and, with the construction industry being responsible for 40% of carbon emissions, it is clear that we need to accelerate our transition to Net Zero.

SD Director Mike Davies met with Senior Associate and Head of Sustainability at Morrow + Lorraine, Stephanie Crombie, to discuss the challenges our industry faces and the innovative solutions we could take advantage of.

Mike Davies – SD Engineers

What are the biggest challenges you see in the construction industry for us getting to Net Zero?

Stephanie Crombie – Morrow + Lorraine

The topic is very complicated and very simple at the same time. The key is to try to work on vernacular and locally sourced regenerative materials.

I would recommend checking UKGBC “Whole Life Carbon Roadmap for the Built Environment”. It illustrates the necessary actions for achieving Net Zero carbon in the construction, operation and demolition of buildings and infrastructure, and it’s quite insightful!

Decarbonisation of the grid is vital. Renewables such as wind and solar will make up a significant proportion but there will still be a shortfall at current rates of progress. Nuclear energy could meet this demand but it polarises opinion and I’m still not sure where I sit on this. It is inherently a low carbon solution but creates dangerous waste which is against circular economy principles and is a major concern.

And, of course, retrofitting is key and so is the decarbonisation of materials.

MD

Can we just rely on offsetting to get to Net Zero?

SC

Offsetting is often presented as a solution, but some reports show carbon offsetting is only 10% effective. It’s also currently much too cheap to offset. This industry needs more legislation to ensure money invested is used effectively. Additionally, we need to consider if we are reforesting that there is a time lag between when the project emission occurs and when the sequestration occurs, meaning there is still a short-term global warming issue.

MD

Accurately assessing the embodied carbon in the construction of a building is a complex task and still relies on a lot of assumptions in the data. How useful is it to count carbon on schemes?

SC

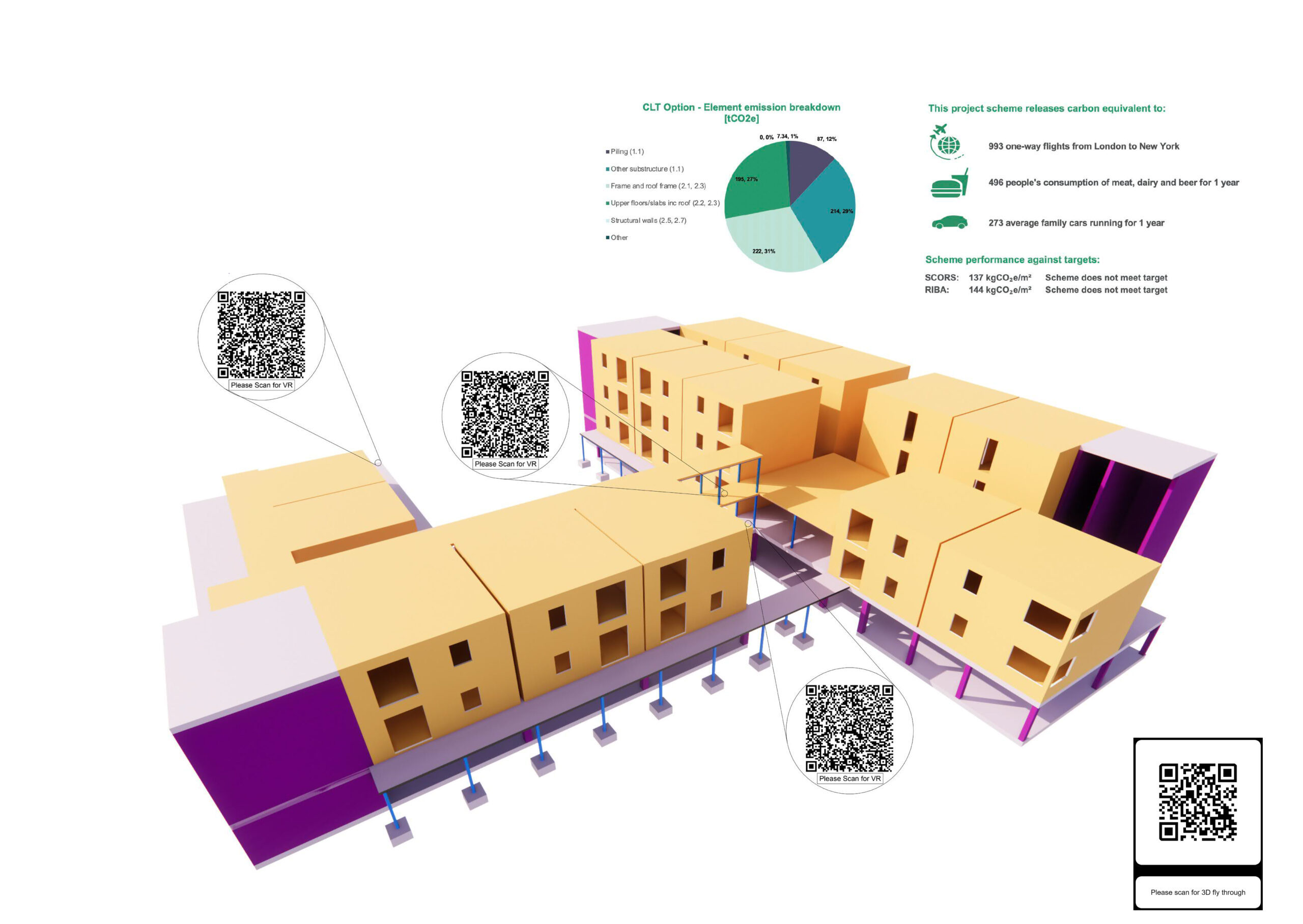

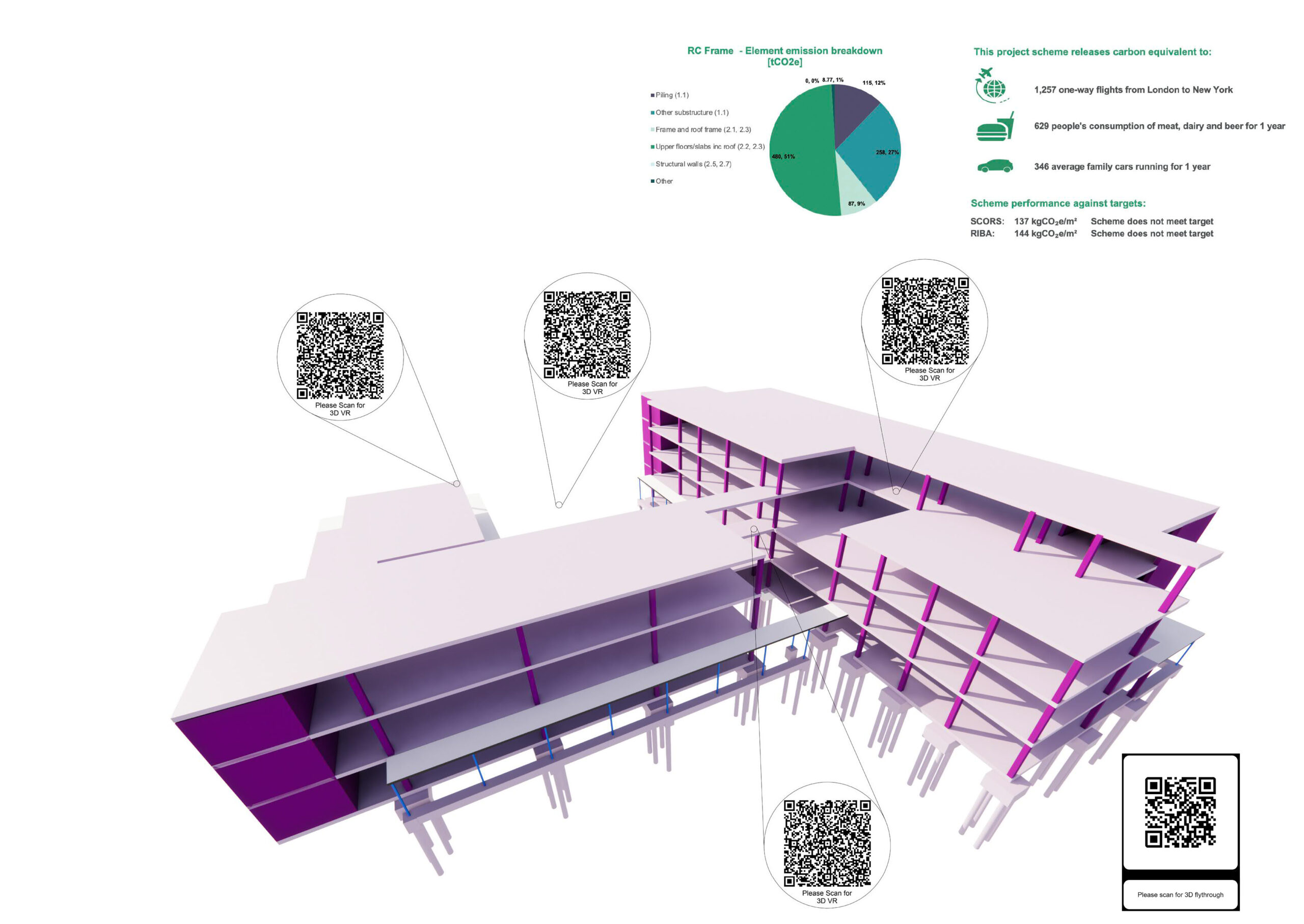

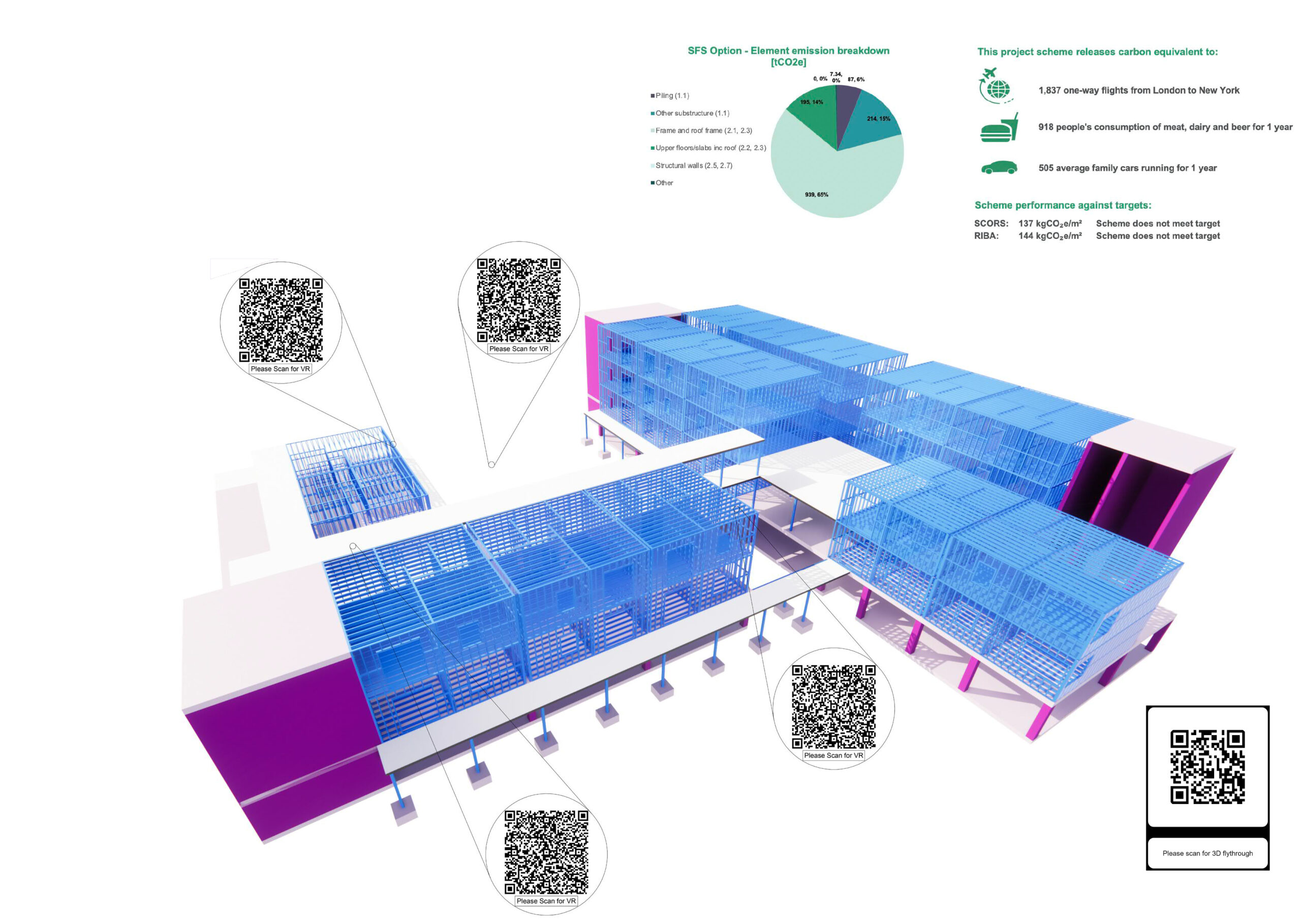

It’s important as it is a very useful tool in looking at the impact of certain decisions. I’d say we need to be careful not to get too wrapped up in the figures but use them to try and compare between different scenarios and allow this to inform more sustainable choices.

Offsetting is often presented as a solution, but some reports show carbon offsetting is only 10% effective. It’s also currently much too cheap to offset. This industry needs more legislation to ensure money invested is used effectively.

MD

There is much debate about demolition to provide a new highly operationally efficient building. Where do you feel the break even point should be when considering embodied carbon and the carbon payback period?

SC

It’s hard to measure and we need to be careful when looking at the data which is trying to make the case one way or another. When looking at a New Build vs Retention it’s also important to look at Retrofit which may balance embodied and operational carbon.

MD

Do you feel timber is the wonder construction material that can help solve the climate crisis?

SC

If sequestration is included in the calculation, then – yes – timber has a lower embodied carbon than steel and concrete frames. The problem is that, often, it is not included in the figures. There are valid arguments on both sides for whether this approach is fair but we need to find a way to ensure the timber does not go to landfill at end of life so sequestration can be utilised.

An additional challenge is that sustainable timber is limited in supply. My thoughts are that we should continue to specify more timber construction and increased demand should lead to an increase in supply through investment in growing more sustainable forests…perhaps replacing some farmland if there continues to be a shift in a reduced meat-based diet..

MD

How successful have you found trying to use reclaimed construction material? What are the challenges but also recent advances you have seen?

SC

The challenge is often finding the supply of reclaimed materials. There are now a few websites which are a good starting point. These include:

Grosvenor’s Material Accelerator

Material exchange – Meridian Water

Timing can become an issue and this often requires the client to buy these materials when they are available rather than traditional procurement models where the contractor often sources the materials.

We have successfully reused bricks on a number of projects.

Reuse of steel introduces constraints to the design which we find clients don’t always want to accommodate.